FAQ – Questions and answers about fire protection coatings

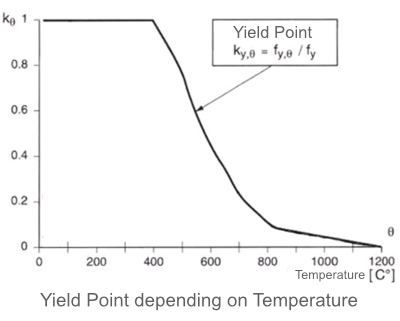

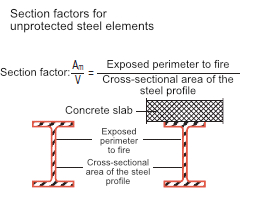

Increasing temperatures in the event of a fire lead to a reduction in the load-bearing capacity of steel components. When the steels critical core temperature is reached, there is a risk of failure, meaning the load-bearing capacity is lost. Fire protection coatings extend the time until the critical temperature is reached as long as possible or as long as necessary. The coatings foam up when exposed to heat (from approx. 200°C) and form an insulating carbon foam (char). The maximum fire resistance duration that can be achieved through the use of intumescent materials depends, among other things, on the underlying standard: The above mentioned conditions are product-dependent. The manufacturer’s instructions must be followed. A general statement on this is not possible. The manufacturers provide information whether systems with or without topcoat are approved. Products specially developed for protection against hydrocarbon fires can even be used in adverse climatic conditions such as offshore structures. To obtain a building authority approval for exterior intumescent materials, outdoor exposure of coated steel plates is required. After 2, 5 and 10 years, aged plates are officially tested again and the approval is extended accordingly. If a top coat is required, it must always be approved by the manufacturer of the intumescent coating, as it must be part of the tested and approved system. In case of small gaps, it can be assumed that the insulation layer builder will bridge them in the event of a fire by foaming. The surface in the gap should be coated as deep as possible. For larger gaps, the void should be filled with mineral wool for example (melting point > 1,000 ° C). For aesthetic reasons, the filling material can be coated with the topcoat of the system used. The manufacturer of the intumescent coating should always provide product- and project-specific recommendations. The section factor is defined as the ratio of the flamed circumference to the cross-sectional area of the profile. There are tables for the commonly used standardized profiles. Thin-walled profiles with a correspondingly large section factor heat up more quickly and therefore require thicker layers of the intumescent. The required layer thickness depends on several factors. These include, among others: It is always important to pay attention to the applications covered by the approval or fire test on which it is based. In the case of different applications, separate test certificates may have to be used as a basis. Different profile types (open sections or hollow sections) have different heating behaviour. For example, hollow sections heat up faster than open sections (e.g. I sections, H sections) with the same U/A factor. Therefore, the coating thicknesses to be applied are determined according to the building component. No maintenance is necessary. The top coat must be checked regularly to ensure that it is undamaged. Damage to the coating structure must be repaired professionally. The manufacturer’s instructions must be observed. The owner of the object is responsible for the inspection. As mechanical damage is largely excluded, maintenance is only required if water damage occurs. We recommend first removing loose dust or other dirt by hand or mechanically, for example by blowing, vacuuming or lightly brushing. However, care should be taken to avoid damaging of the coating. Further cleaning procedures depend on the product and should be coordinated with the respective manufacturer.

General questions about fire protection coatings

Questions on the use of fire protection coatings

Questions about the application of fire protection coatings

Questions on the dimensioning of intumescent materials

Questions about care and maintenance of fire protection coatings